Our Projects

Real solutions for real commercial building challenges

Featured Project: Dulux Testing Laboratory Facility

Project Scope: Complete Plumbing, Electrical and Mechanical Installation

Plumbing, Mechanical, and Electrical Services for Testing Lab Workshop. Delivered on time and on budget.

CBS completed the plumbing, mechanical, and electrical installations for the new testing lab at Dulux. The lab features a heat recovery system that uses stale extract air to temper incoming fresh air.

A hybrid VRF system was installed to provide climate control for both the office and lab areas, ensuring the specified temperature.

A climate control room where temperature and humidity levels are maintained to a desired set point. Additionally, a paint booth and fume cupboards were installed and commissioned.

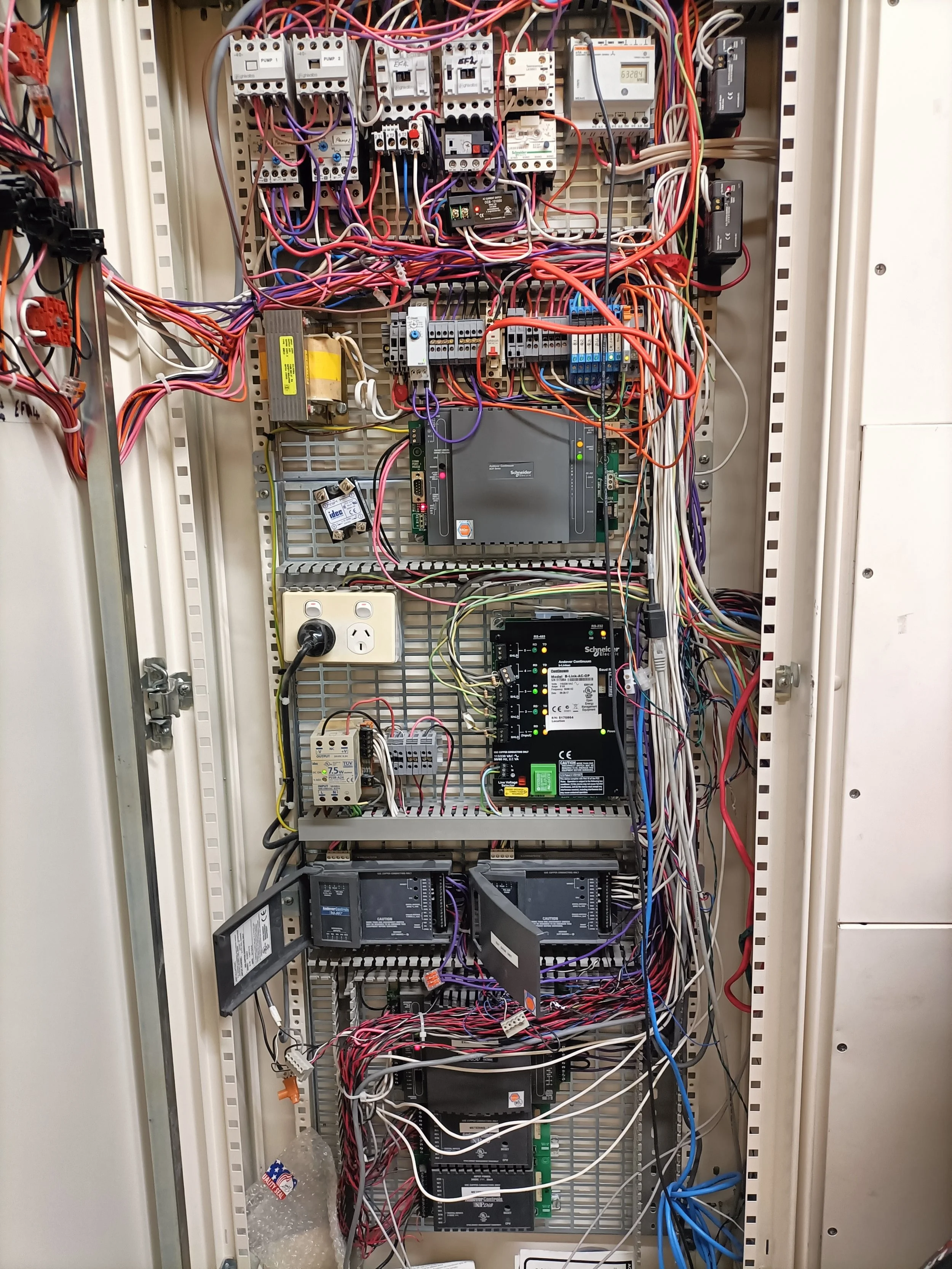

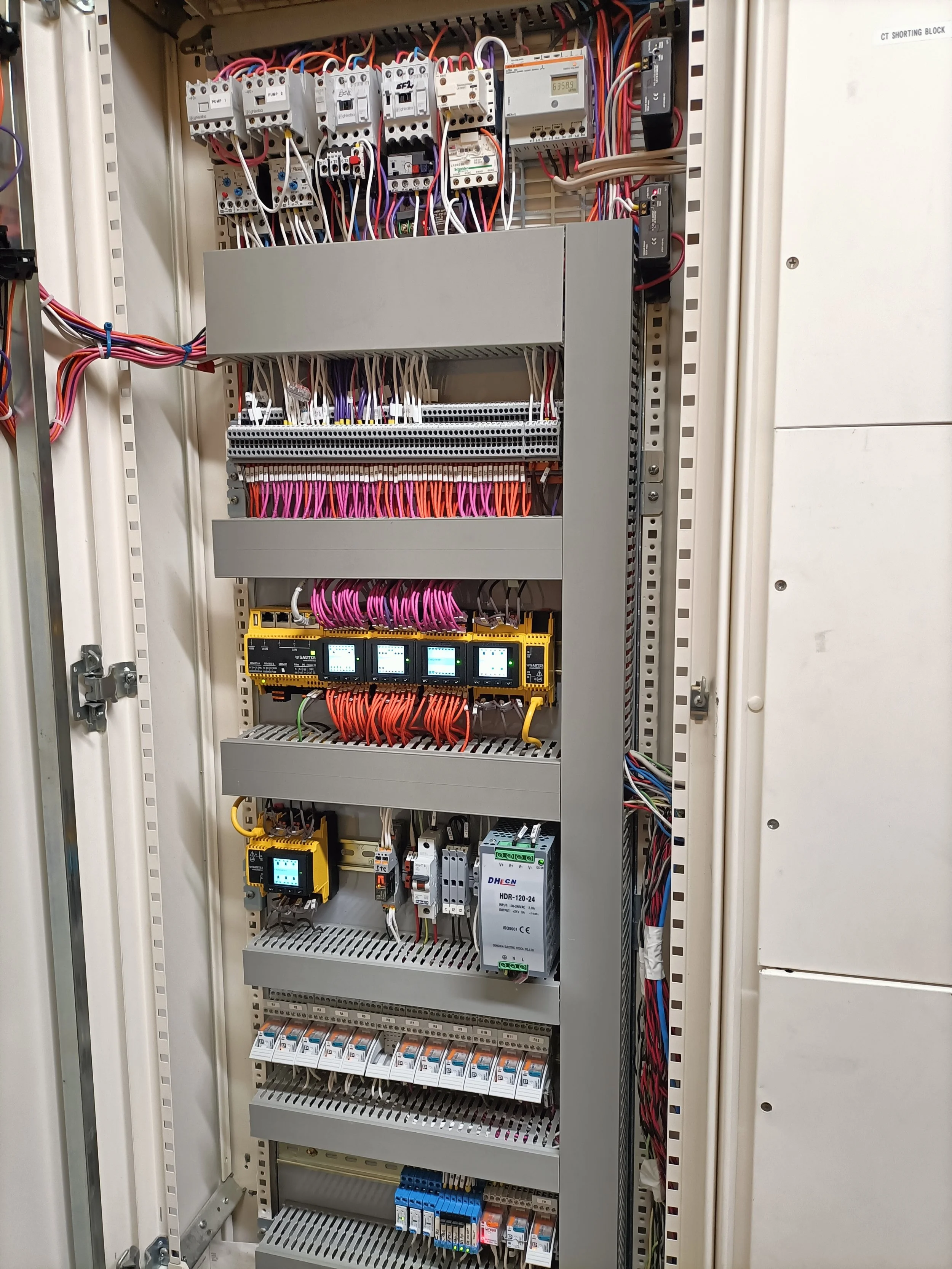

The BMS system was integrated to control all mechanical plant operations. Plumbing works included the installation of cold and hot water systems throughout the site, as well as the installation of hot water cylinders. Pneumatic pipes and an air compressor system were also installed and commissioned.

Challenge: New laboratory facility required precision HVAC systems for temperature-sensitive testing environments. Strict compliance requirements and tight deadlines.

Solution: Custom-designed HVAC system with precision controls, redundant safety systems, and comprehensive monitoring. Full IQP certification process managed from design to commissioning.

Results:

Project completed on time and on budget

Zero system downtime in the first year of operation

Recent Projects

TransPower Substation Facility - HVAC Retrofit

Challenge: Aging HVAC system in critical infrastructure facility requiring 24/7 operation.

Solution: Phased retrofit allowing continuous operation during upgrades.

Results: Zero downtime, 24% energy savings, extended equipment life.

Central Park Commercial Complex - Ongoing Maintenance Contract

Building 8 previously utilised an outdated BMS system. Upon CBS assuming the building contract, we were tasked with investigating the building’s high power consumption.

Our investigation revealed that failed BMS points resulted in certain plant items running continuously, leading to excessive energy use. The front-end BMS computer offered limited visibility into the building’s operations.

In response, CBS installed a new, cloud-based BMS system, reducing power consumption and providing the capability to remotely access and monitor building operations from any location.

Challenge: Large multi-tenant building with diverse HVAC needs and previous contractor reliability issues.

Solution: Comprehensive maintenance program with predictive monitoring and tenant-specific comfort management.

147 Lambton Quay Ground Floor Fit-Out

CBS provided mechanical and electrical services for the fit-out at 147 Lambton Quay. This included the installation of two heat recovery units, which use stale extract air to temper incoming fresh air, and the installation of 700 meters of solid ductwork to facilitate heat recovery. Fan coil units were installed to leverage the building’s main plant for heating and cooling needs.

BMS controls were integrated to connect with the building’s existing BMS system. Delivered on time and on budget.

Facing a similar challenge?

See how CBS can solve your specific building maintenance and compliance needs

Call us: 0800 377 344 | Email: office@cbsservices.co.nz

Want to see more?

These projects represent just a sample of our commercial building solutions. Each project is unique, but our approach is always the same: understand the challenge, deliver the right solution, and ensure long-term reliability.